Although used since ancient times, aluminium became a key material in architecture after the 1920s, when anodising was developed, creating the anodised aluminium, highly resistant to corrosion.

Anodising aluminium, an overview

Anodised aluminium is aluminium that has undergone an anodising process, an electrochemical oxidation process in which a protective layer of oxide forms on the surface of the metal to be treated. Anodising treatments, generally applied to protect aluminium alloys, improve the surfaces, both in terms of mechanical strength and aesthetic appearance.

The first anodising aluminium process was developed in 1923; the most widely used process in industrial production dates back to 1927 and uses sulphuric acid. The thickness of the anodisation can be adjusted by varying the treatment time and current intensity. In anodising aluminium processes, a lower thickness is generally preferred in decorative applications, while higher ones are preferred for external use. Both allow the use of colors and are, therefore, more suitable for use where there is a greater demand for decorative elements.

Anodised aluminium: design applications and uses

As we have seen, anodising aluminium enhances the metal’s quality and makes it even more resistant and efficient. At the same time, through the use of different oxides and colours, it is possible to create unique designs that help drive the adoption of this material across different industries.

Anodised aluminium: the advantages in architecture and design

1. Wear resistance and color durability

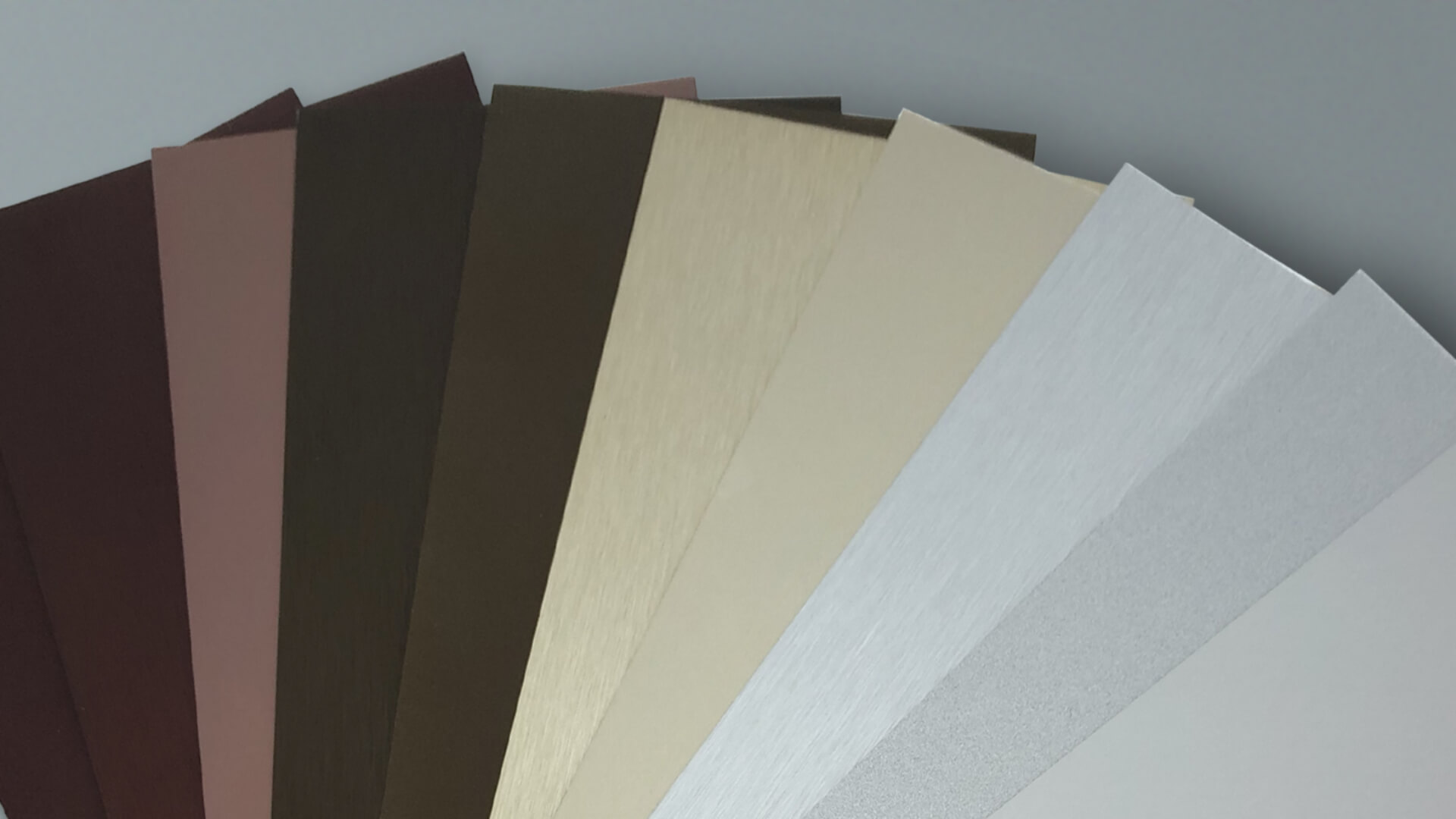

Anodising aluminium allows the material to become very resistant to corrosion and delamination. The surface is perfectly uniform, and the color is thus more brilliant and “metallic”, both on smooth and textured surfaces. Depending on which anodising aluminium treatment is chosen, the color changes and perfectly reproduces many different metals, from gold to copper, from titanium to iron, from brass to bronze. The color is achieved by immersion. Aluminium thus absorbs the colored pigments and lasts very long, thanks to its resistance due to intimacy between the metal and the oxide layer

These features make it particularly suitable for indoor and outdoor use. Strength, versatility, wide range of colors enable aluminium for use in an infinite number of projects, where the only limit is the creativity of the architect or designer.

2. Lightweight: perfect for construction and interior design

Aluminium is extremely lightweight, weighing a third less than, for example, steel. The advantage of anodisation is that it does not alter the weight of the final product. All the requirements listed so far – different thicknesses of anodisation, the long-lasting color resistance and resistance to corrosion, lightweight – make it a material perfect for architecture, industrial design, and interior design.

In furniture, a use which is not yet so widespread but which has great potential unexpressed, is in furniture structures, kitchen cabinets, and, of course, doors and tops. The wide range of textures and finishes allows anodised aluminium to be used alongside other materials for high-end products.

Although it did not come into common use until the 20th century, aluminium has been used in architecture since the late 19th century. One of the most representative examples of anodised aluminium’s resistance to corrosion and wear is the Empire State Building, an icon of Art Deco architecture. The aluminum frames of the facades of the New York skyscraper were only replaced, thanks to anodisation, in 1994, while the building dates 1931, making a perfect example of the advantages of anodising aluminium for building design.

3. Anodised aluminium for contemporary architecture

More recently, anodised aluminium has been used extensively in a contemporary building, which is not yet an icon but is a candidate to become one: the Burj Khalifa in Dubai. For the façade of the Emirates skyscraper, aluminium was used for reflective glazing, together with glass panels, textured stainless steel spandrel panels and stainless steel vertical tubular fins. The weight of aluminium in the Burj Khalifa’s façade is equivalent to the weight of five Boeing A380 aircraft.

Another significant example of the decorative power of aluminium, when used skillfully, is the Selfridges department store building in Birmingham, a project by Future Systems. Here, 15,000 anodised aluminium discs are placed on a blue background, enveloping an organically shaped shell. Aluminium thus becomes a material with an evocative power, the ideal complement for creating an icon with a strong visual identity. And, as we have seen, through manufacturing techniques, such as anodising aluminium, this material becomes even more promising, thus allowing companies to think on innovative applications for this material.