With over 60 years of experience in the aluminium surface treatment, mechanical deformation and a strategy based on continuous innovation, Almeco is a real partner for any customers’ solution. In fact, thanks to its extensive experience and strong investments in R&D, the company can offer a wide portfolio of services tailored to customers’ needs.

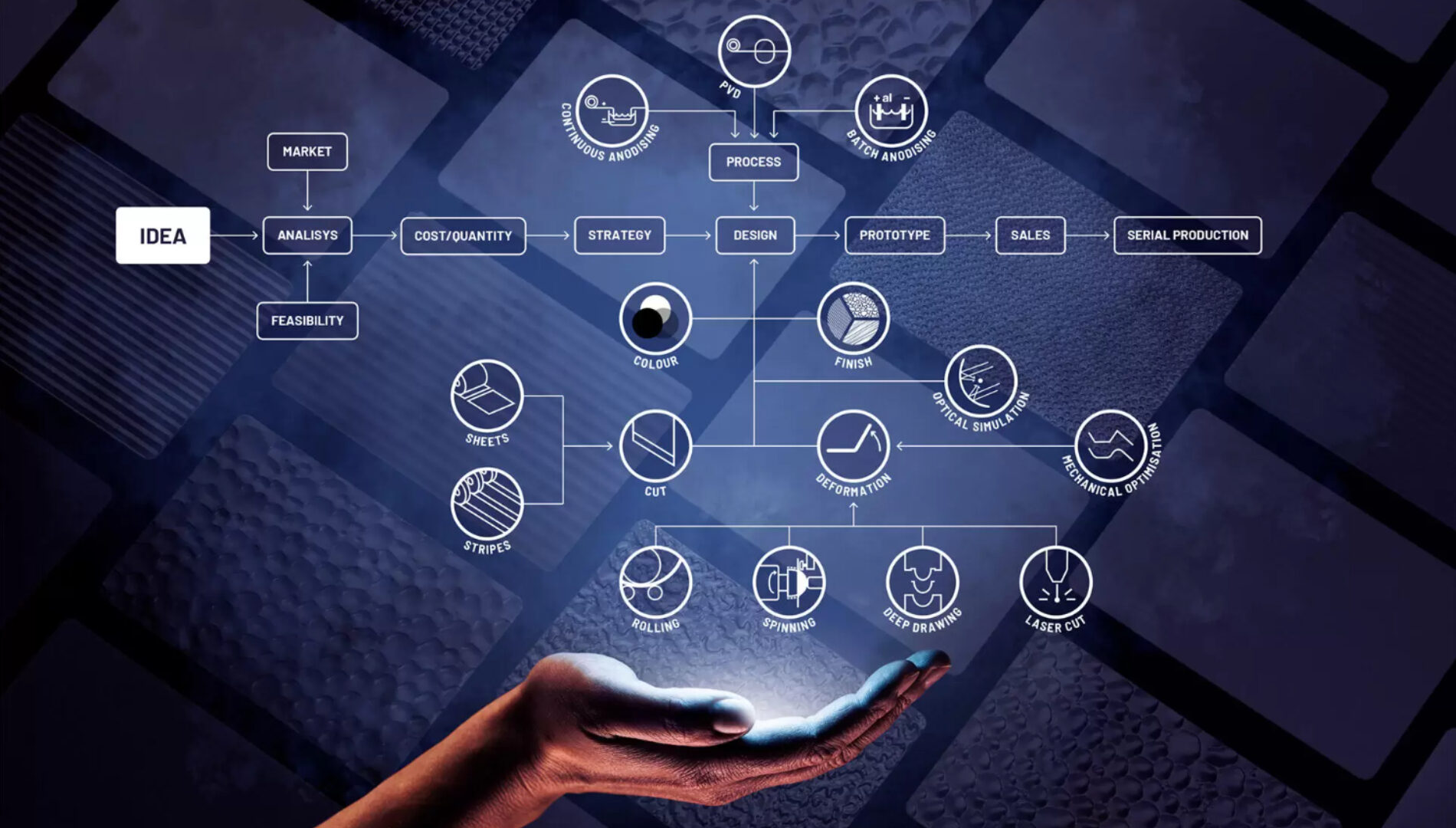

Design, engineering, prototyping and production: Almeco offers an all-in-one approach where the customer can step in at any stage, depending on specific needs. From the initial support to define the idea and its feasibility to the evaluation of costs and specific skills required during the production phase.

An approach that allows customers to cut production time and costs, and to evaluate the component before mass production, thanks to fast prototyping service.

A portfolio of services highly customizable to customers’ needs

Each company is different from another, and Almeco knows this very well. Its portfolio offers a wide range of services, from ready-made bandoxal® surfaces to the creation of a product with completely new colours and materials.

Regardless of the entry stage (design, engineering, prototyping or production), the company follows its customers step by step until the creation of the final product.

This makes Almeco’s services suitable for any organisation, regardless of size and internal structure. For example, companies able to carry out the development phase internally can turn to Almeco for other steps, such as engineering and prototyping.

Other companies, on the other hand, may need advice right from the beginning, i.e., with the idea of the product or component to be developed. Or perhaps the company has specific targets to meet in terms of costs, materials, performance, and handling.

A zero-surprise approach

This is where Almeco’s consultants’ extensive experience in lighting and in the aluminium process comes in. They are able to guide the customer in the choice of the right material, identifying the ideal process to meet specific needs (PVD, continuous anodising or batch anodising).

After defining the strategy, the designing stage can begin. Here, thanks to Almeco’s investments in state-of-the art designing software, the client can observe the specifics of the component and evaluate adjustments as required.

Almeco’s specialists evaluate together with the customer every change that must be made and determine how it will affect the final result, in terms of quality, performance and costs.

This holistic approach that involves the customer every step of the way guarantees a zero-surprise outcome.

Aluminium process, how to follow a smart approach

The whole process is designed to be efficient, flexible, and fast. Almeco understands businesses’ needs to cut costs and time-to-market in highly competitive markets that change at a very fast pace.

That is why, before proceeding to the production phase, Almeco’s specialists realise a prototype of the component or the product using a fast-prototyping tooling service (including, when needed, 3D printing for additional plastic components). This allows customers to evaluate the object closely and check the specifics, before mass production.

It also gives the possibility to clients to prepare in advance all brochures and advertising material relating to the new product. Thereby, customers have all the material ready for market launch or they can present the product even before it is mass produced.

Experience and continuous innovation: why Almeco is a strategic partner for your business

This approach is possible thanks to Almeco’s business model, structured at an international level in units specialised in all different phases of the industrial process.

A company that over the years has acquired an international dimension but is determined to remain close to its customers. And it can do so thanks to its constant investment in plant and equipment.

In fact, innovation is a key part in the Almeco Group’s strategies. The company’s R&D team is constantly engaged in product and process innovation, through partnerships with universities and research institutes.

This allows the company to offer processes and products that are tailored to customer needs, but that also respond to change in demand.