In the ever-evolving landscape of Architecture and Interior Design, the dynamics of aluminium treatment have undergone a remarkable transformation in the last decade. As a key player in this industry, it became necessary for Almeco to adapt to shifting market demands, particularly in response to the diminishing use of aluminium in lighting applications. A commitment to excellence and continuous advancement in aluminium treatment technology that that defines its core values.

Embracing a proactive approach, the company recognized the changing trends and sought to redefine the applications of aluminium in the construction and interior design sectors.

That is the reason why, in the last decade Almeco has started a process of diversification of our production thanks to its know-how in aluminium treatment.

This process is the result of a shift in the market of aluminium applications that the company has experienced in recent years. In particular, it was noticed that due to a technological evolution of sources in the lighting sector, a process that began about ten years ago – with the shift of traditional incandescent and sodium sources to LED sources – the volumes of aluminum used in the field of lighting were gradually decreasing.

The brand has decided to react to these changes in the only way they knew how: with a proactive approach that has led to explore new opportunities regarding aluminium treatment and resulted in changes to both the production lines and their offering.

These efforts that were put on the ground allowed Almeco to remain a key-player in an ever-changing industry.

Exploring new applications: the Growing trend of aluminium treatment in Construction and Interior Design

The change in demand for lighting solutions has prompted Almeco to look for different and new applications of aluminium panels and surfaces. A predisposition for change that allowed to catch in advance trends that were already emerging in the global market and were spilling over into the European market as well, as in the case of the increasing focus on aluminium in the construction and interior design industries.

So, the company decided to shift its focus from lighting applications to interior decorations, while still maintaining the lighting range and looking at the industrial and decorative outdoor market.

Architects are showing a growing preference for integrating anodised aluminum into their projects. In Europe, there is a rising trend of adopting this concept, which has already been observed in the Far East and Gulf countries. Anodised aluminum is extensively utilized as a cladding material for skyscrapers in these regions.

Enhancing aluminium treatments for outdoor applications: the launch of the dedicated line in 2016

This decision allowed the company to explore new aluminium treatments optimised for specific application needs. Materials intended for outdoor applications, in fact, are subject to different environmental conditions and application requirements – in terms of safety, industry standards, efficiency, reflection and much more – than surfaces intended for indoor applications.

To meet all these needs and ensure a product that can withstand outdoor applications, an intervention on the material and oxide applied to the surface thickness was needed. This meant that it was also necessary to adapt the treatment of the aluminium, and the line where this treatment is used, to the new requirements.

In 2016 Almeco launched a surface treatment line for the types of materials defined as high thickness, making it possible to process materials up to 3.2mm in gauge, coil widths up to two meters, and oxide thicknesses up to 25 microns.

The new line allowed the brand to expand our offering, with very good feedback from the market. Today, architects and construction professionals have increasingly become part of the customer base, leading to the decision to invest in a new line dedicated to the building & construction sector, which is already in production.

Expanding possibilities: advancing aluminium treatment for customisation and innovation

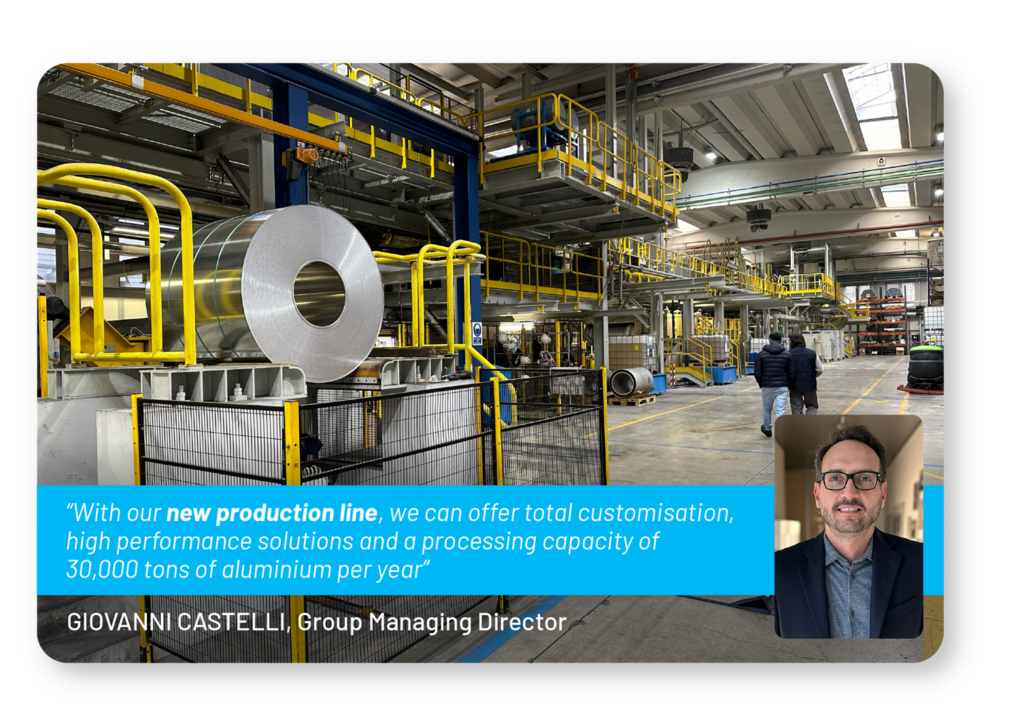

With the introduction of the new aluminium treatment line, Almeco is thrilled to enhance its flexibility and expand the production volumes for design, construction, decoration, and the technical industrial sector. This significant step allows the company to achieve an impressive aluminum treatment capacity of approximately 30,000 tons per year.

One of its key strengths lies in offering complete customisation of products, catering to specific requirements such as colour, finish, and oxide thickness based on the application context. Whether it’s stock production or specially tailored aluminum for unique projects, Almeco is committed to bringing to life the most innovative and extravagant aesthetic and technological ideas conceived by architects and designers.

Furthermore, Almeco recently decided to invest in an additional aluminum surface treatment line. This dedicated line will primarily focus on special, selective coatings, optimising the aluminium’s resistance, irradiation, and adhesion characteristics.

This investment reaffirms the company’s commitment to continuously pushing the boundaries of aluminum treatment and delivering exceptional solutions for its valued customers.