Ideal for applications in architecture, furniture, interior design, as well as for making industrial design products, aluminium sheets have become very popular among architects. But not only that. In fact, thanks to its many qualities, aluminium is used in a wide range of applications, from lighting to consumer electronic, to renewable energy production or even for increasing the yield of agricultural crops in greenhouses.

With more than 60 years of experience in aluminium treatment, Almeco has about 30,000 square meters of manufacturing facilities dedicated to this metal which is treated in a continuous coil anodising process. The company can offer a complete portfolio of services, starting from the design of the individual aluminium surface to final and customised production. Working closely and in full cooperation with its customers, Almeco can be a single reliable partner capable of providing the perfect product for each project, with an innovative approach always based on research and development of the best solution.

Aluminium sheets, two treatments, many applications

With its extensive experience in aluminium treatment, Almeco has the know-how and technology to bring out the most relevant qualities of aluminium for each project.

Almeco’s aluminium sheets are the result of two main treatments used in Almeco’s plants: continuous coil anodising and PVD (Physical Vapour Deposition).

Aluminium anodising, also known as “anodic oxidation”, is an electrochemical process by which a protective layer of aluminium oxide grows on the surface and protects it from corrosion and wear.

Continuous coil anodising, compared to traditional batch anodising, has several advantages: first of all, the production efficiency, versatility and sustainability. In addition, the surface quality is more homogenous, with a better aesthetic and tactile feeling, ensured by the absence of hanging or racking marks.

The treatment allows to improve aluminium’s resistance to weathering, its durability, insulating capacity and, therefore, also its sustainability. Through the anodising process, aluminium surfaces can be treated differently and fully customised, so it is possible to obtain different finishes and effects, depending on the application and the desired result.

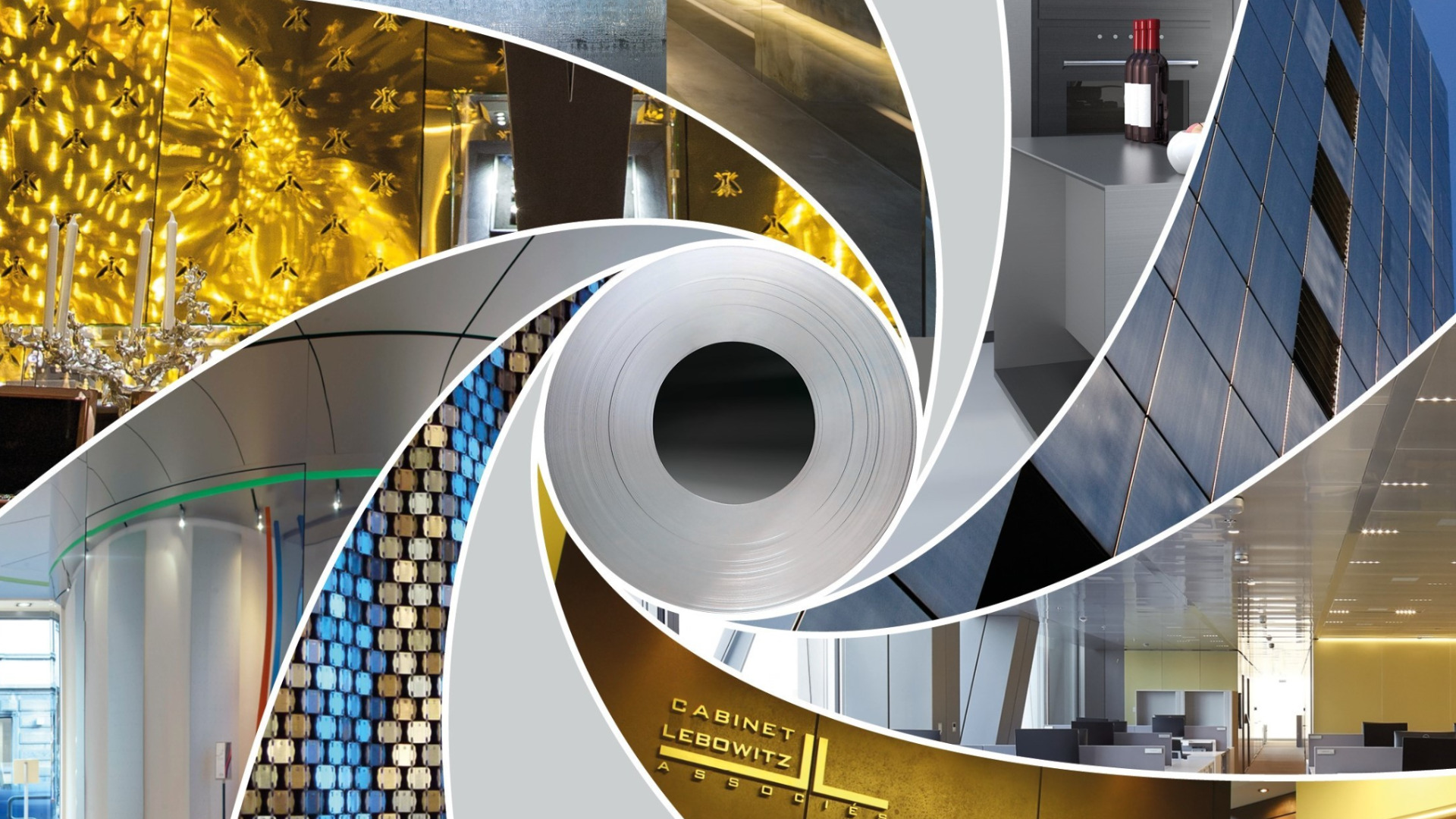

In fact, Almeco’s bandoxaldecor® Business Line offers aluminium sheets in multiple colours with the possibility of obtaining embossed, brushed, specular and textured finishes. Almeco’s ability to combine the qualities of aluminium with elegant yet high-performance designs have made its aluminium sheets ideal for a wide variety of applications, from automotive to consumer electronics, lighting, interiors and many other.

New applications and innovations with Almeco’s approach

The company’s lifelong focus on customer needs – combined with the deep knowledge of aluminium, an extensive network of partners and an unwavering commitment to innovation – has enabled Almeco to expand the fields of application of its aluminium sheets.

The Bernburg plant, which is dedicated to PVD treatment, has played a large role in this journey.

PVD is a treatment that allows to enhance the optical performance of aluminium to promote efficiency. It’s a coating process focused on the application of thin metal and ceramic multi layer structure in vacuum by physical means. This is a very flexible process: depending on the materials used for coating, in fact, it is possible to modify the multilayer to enhance the optical qualities of the surface.

The high flexibility and productivity of the line, combined with the know-how of Almeco’s experts, has enabled the company to develop high performing surfaces for special applications in the field of solar energy, sanitising, horticulture and for medical applications.

From e-commerce to custom solutions: one partner for all your needs

Responding to customers’ needs in the best possible way has always been the company’s goal, that’s why Almeco has always placed efficiency, speed and customisation at the centre of its services.

Thanks to its experience in aluminium treatment, Almeco knows that each project is different from the others, both in terms of the product’s requirements and preparation time. To make its service even faster, the products most popular with customers in the bandoxaldecor® Business Lines are now available on the company’s e-commerce as pre-cut sheets (1250×2500 mm standard size) with a preparation time of only three days.

The focus on customisation, another key value for the company, is not missing from the e-commerce, thanks to the possibility to order personalised aluminium sheets online as well (with 15 days of preparation time).

And for those applications that need even more customisation, Almeco’s experts are available to design and develop custom projects. An approach that involves from the earliest stages the customer, so as to guarantee the best results.

From aluminium sheets to product: why Almeco is the right partner for your aluminium projects

The advantages of choosing Almeco for your projects are several. First, the well-established custom design and development processes are carried out in such a way that the client is constantly involved (starting with the feasibility study) to ensure the best outcome. Customer involvement is also fostered by physical proximity, thanks to the company’s 3 subsidiary and distributors all over the word.

In addition, the extensive network of partners developed over the years allows the company to have an optimised supply chain that enables the reduction of procurement time for the resources needed to develop a project.

Whatever the application needs, Almeco’s experts are always at the customers’ side to develop their projects, from aluminium sheets to product.