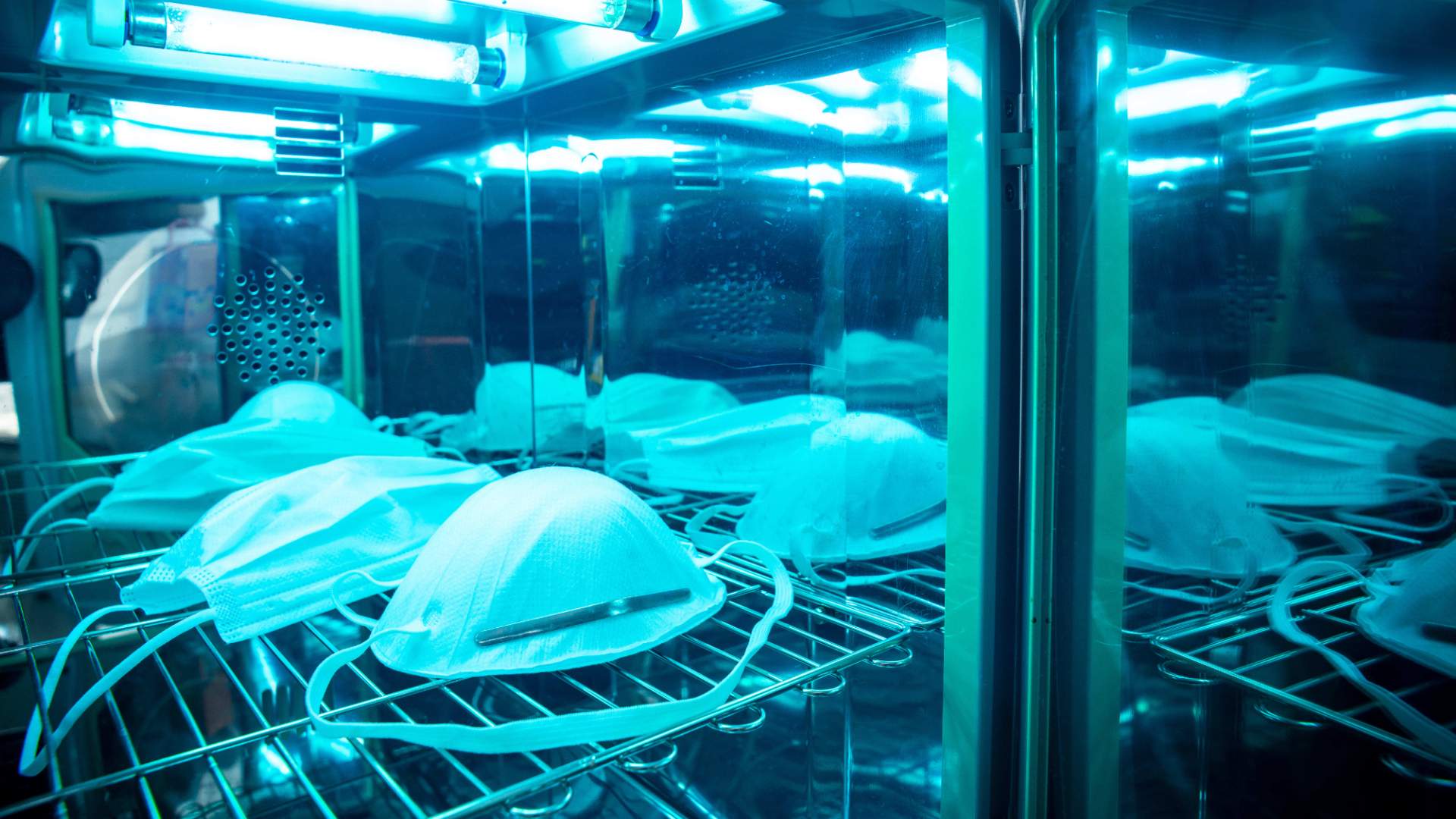

Sanitizing air, objects and surfaces has become a necessity of our times, even more so since the spread of the Covid-19 pandemic. This disruptive event has led to an increase in the marketing of ultraviolet germicidal lamps, used to sanitize environments: these lamps exploit the ability of ultraviolet radiation to kill bacteria and neutralize viruses by making them inactive.

By activating photocatalytic surfaces, ultraviolet light helps sanitize environments by breaking down organic molecules, destroying viruses and bacteria as well as helping to remove any organic residues.

UV-C radiation is absorbed by the DNA and RNA of harmful microorganisms, modifying their structure, and reliably blocking their reproduction with a sufficiently powerful radiation intensity. There are several sanitizing systems used for this purpose, including those that use reflective surfaces made of aluminum, which are very effective.

The qualities of aluminum and use in UV sterilization

Aluminum is a lightweight material that can be completely and repeatedly recycled: its characteristics never change even after countless reuses. Ideal for the circular economy, it is resistant to corrosion and abrasion and is particularly ductile. In short, it is an essential and 100% sustainable resource. But it is not only its excellent technical and ecological characteristics that are important. The use of aluminum in some areas, such as UV sterilization, is also particularly beneficial for the safety of people and environments.

How aluminum surfaces for UV sterilization are produced

Aluminum surfaces are highly reflective and come into play when it comes to designing equipment capable of sanitizing and UV sterilizing environments.

Almeco uses innovative technologies and engineering know-how in its European factories to produce reflective and homogenous aluminum surfaces. Production uses anodizing and PVD – Physical Vapour Deposition processes – of the highest quality. Thanks to in-depth knowledge of the mechanical and optical characteristics of aluminum, Almeco is able to offer surfaces with excellent performance.

Reflection, an outstanding feature for UV sterilization

In order to achieve the most efficient reflection characteristics, ideal for UV sterilization processes, Almeco uses the latest PVD technologies, involving continuous controlled deposition of thin films – metallic and ceramic. The process takes place in a vacuum and leads to the creation of a coating composed of ultra-pure nanometer-thick layers, which provide the metal with exceptional light reflection performance up to over 98%.

The special surfaces produced by Almeco that can make use of non-visible UV-A, UV-B and UV-C radiation are three different types belonging to the vega®UV range. They offer high performance precisely in sanitizing and sterilizing applications, but also in medical, curative or forensic applications.

vega®UV-C for sanitization and UV sterilization

To accelerate the sanitizing power of UV-C rays, Almeco has developed the vega®UV-C reflective surface using Physical Vapour Deposition technology. The coated aluminum is placed closed to lamps or LEDs that emit ultraviolet light to sterilize and disinfect surfaces, rooms, and objects. Increasing the effectiveness of UV systems for sterilization, the vega®UV-C aluminum surface achieves 91% reflection of ultraviolet rays. Used to coat the inside walls of sanitizing equipment and systems, the reflective surface helps to enhance the sanitizing power of UV-C rays and to reduce the exposure time. The high reflectivity of the surface developed by Almeco thus helps to increase the efficiency of a very reliable, fast, and environmentally friendly method of sterilization and sanitization, which does not require the use of any chemical agents that are harmful to health.

Almeco is able to support customers, with the collaboration of its optics designers, to develop and produce reflectors capable of optimizing UV radiation emission, concentrating and directing it precisely where it is needed, avoiding dispersion, with high levels of efficiency and performance.