Efficiency, strength, and lightness are the three fundamental properties that have made aluminum increasingly popular in the construction industry, especially in green building. This versatile material is particularly well-suited for panelling ceilings, offering a range of benefits that make it a top choice.

When it comes to panelling ceilings, aluminum provides a seamless solution: its easy adaptation to any architectural requirement ensures a perfect fit for ceilings of any shape or design. Whether it’s a curved or angular ceiling, aluminum can be effortlessly shaped to meet the desired specifications, allowing for unique and visually appealing designs, such as 3D shapes and effects.

With a high level of expertise in aluminum treatment and an extensive catalogue of aluminium surfaces – which differ in finish and colour – Almeco has developed aluminium surfaces optimised for ceiling applications.

The rise of aluminum for panelling ceiling applications

Metal ceiling tiles have been used in construction as decoration for thousands of years. As one of the most lightweight metals available, aluminium is often preferred in these applications as it brings unique advantages, including:

With growing interest toward green building and building efficiency, we can expect to see this metal increasingly employed in construction, both in the design of new buildings and in efficiency upgrades to existing buildings.

Aluminium surfaces for panelling ceilings, how to choose the right partner for your project

This focus on sustainability from the market and its various stakeholders drives companies specialising in the treatment of this metal to design optimised surfaces for ceilings panelling applications that meet the requirements of efficiency, safety, and sustainability. A commitment that requires both an in-depth knowledge of aluminium treatment and a strong commitment to innovation and the continuous search for new (or optimised) solutions to meet application needs.

These are the factors that characterise the approach of Almeco, which, with over 60 years of experience in aluminium treatment and innovative production lines, has built up a portfolio of optimised aluminium surfaces for applications in various industries.

The company’s offering includes pre anodized aluminium surfaces designed for panelling ceiling applications, such as bandoxalε®, a high-emissive aluminium surfaces for climate control, bxdecor a wide range of textured and coloured surface for decorative applications, and bx3D a collection of three-dimensional aluminium surfaces dedicated to architectural and interior design applications.

Paneling ceilings: aluminum takes shape with bx3D

bx3D is a collection of three-dimensional aluminum surfaces dedicated to architectural and interior design applications. The surfaces come with different finishes: stripes, cross, dune, diamond and wavy, with a wide choice of colours.

bandoxalε, high-emissive aluminium surfaces for climate control

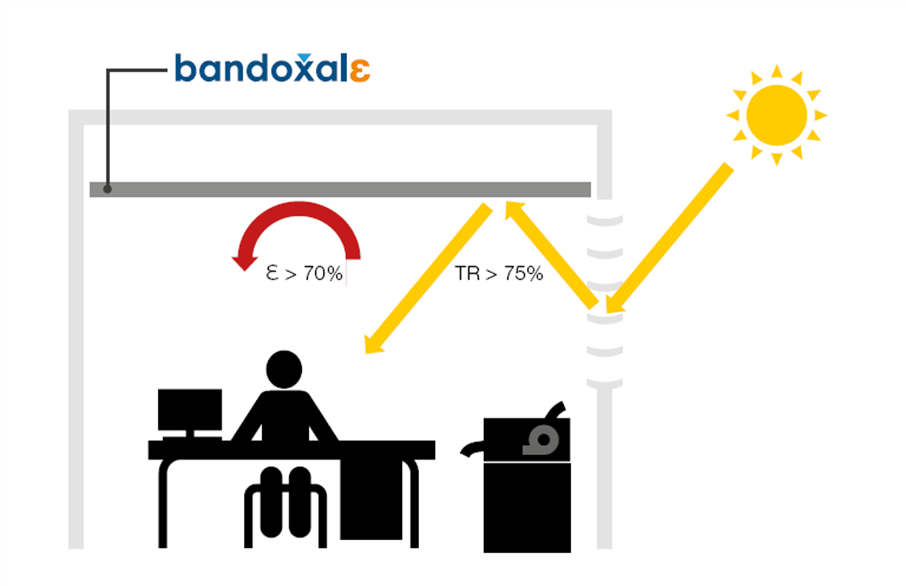

bandoxalε is a high emissive finish developed by Almeco’s R&D team for applications in climate control ceiling, available in different colours and finishes.

The functioning of climate control ceilings is based on the principle of radiation. Cooling/heating coils are concealed behind the climate-control panel, acting as a heat exchanger. During the summer, the panel absorbs heat from the room and transfers it to the cool water circulating through the coils. In winter, it radiates the heat from the warm water circulating in the coils throughout the room quietly and without any air movement, creating a pleasant temperature gradient. These climate-control panels resemble regular suspended ceiling panels and can also be used for retrofitting purposes.

In bandoxalε, the thickness of the anodic oxide layer – which enhance certain qualities of aluminium, as well as providing another level of protection – has been optimised to find the right balance between thermal emissivity and light reflectance.

bxdecor pre-anodised aluminium for panelling ceilings applications

Pre-anodised aluminium is a versatile material that proves to be highly effective for both ceiling and cladding applications. Its use is not limited by climate conditions, making it a suitable choice in various environments.

One of the main reasons to install a dropped ceiling is for aesthetic purposes. Coloured panels in different shapes and combinations can be used to hide differences in height and materials in the underlying ceiling structure.

Additionally, a dropped ceiling allows for seamless integration with building infrastructure, concealing piping, wiring, ductwork, as well as lighting and sprinkler systems.

The acoustic benefits of using perforated panels further enhance the practicality of a dropped ceiling. By utilising the ceiling plane, it is possible to reflect both natural daylight and electrical illumination, maximising lumen efficacy and improving the comfort and usability of interior spaces.

bxdecor is Almeco’s line of pre-anodised surfaces developed for decorative applications, which allows the excellent qualities of aluminium to be combined with a wide range of colours (more than 50) and finishes (profiled, brushed, specular, and textured) that allows designers and architectures to give a touch of originality to their creation.